For years, 3D printers have remained largely niche tools—more suited to workshops than living rooms. But the Bambu P1S Combo is changing that. This machine delivers impressive speed and quality with minimal fuss, making 3D printing accessible even for beginners. Within days of setup, users can confidently start prints from anywhere, knowing they will finish reliably.

Speed and Print Quality

The P1S excels in speed. While older models like the Creality Ender 3 Max Neo struggled to exceed 150mm/s, the P1S easily surpasses 200mm/s without compromising quality. The printer is so fast that its vibrations can cause minor imperfections on sharp corners, but this is easily corrected by reinforcing the printing surface.

The P1S addresses common failure points with a unique nozzle cleaning system. Before each print and filament change, the machine extrudes excess material into a dedicated waste chute. This prevents nozzle clogs and ensures clean first layers. While elegant, this system isn’t perfect—waste plastic falls out the back, requiring manual cleanup or a user-printed “poop chute” for containment.

The printer also auto-levels the print bed, warning users of obstructions like leftover supports. Unlike some older auto-leveling systems, the P1S requires no manual adjustments, maintaining accuracy over weeks of use.

The AMS Bundle: Convenience Over Complexity

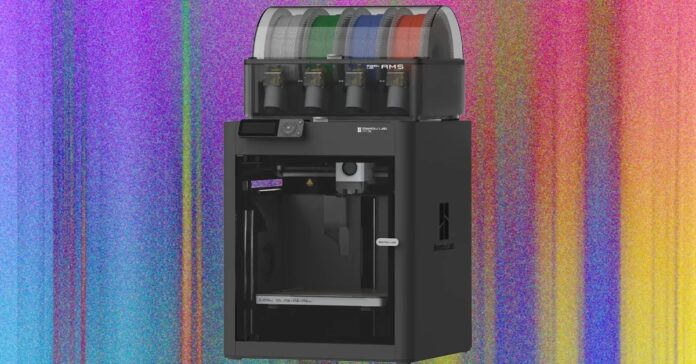

The P1S is available on its own, but the combo with the Automatic Material System (AMS) is worth the extra investment. While multi-color prints are possible, the AMS shines in streamlining filament changes.

Switching filaments manually can be time-consuming: heating the nozzle, removing old filament, pushing in new material, and ensuring proper spool positioning. The AMS automates this process, allowing users to load multiple colors and materials at once. The machine handles heating and purging automatically, eliminating manual filament swaps.

The AMS also supports Bambu’s filament spools, which contain chips that communicate material and color data to the slicer software. Third-party filaments can sometimes cause synchronization issues, requiring manual adjustments in the slicer. The AMS uses two numbering systems—one for the software and another for physical positions—which can be confusing, but is easily corrected by cross-referencing in the slicer.

A Shift in Approach

The Bambu P1S Combo isn’t just faster; it changes how users interact with 3D printing. The machine handles tedious tasks like bed leveling and nozzle cleaning, allowing users to focus on designs rather than troubleshooting.

Minor software quirks and plastic cleanup are negligible compared to the overall convenience. The P1S eliminates the need for perfectly optimized settings or meticulously sealed filament storage, making 3D printing more approachable for both beginners and experienced users.

For those seeking a user-friendly 3D printer with minimal setup and maximum output, the Bambu P1S Combo is an excellent choice.